HOW TO READ AND UNDERSTAND A WHEEL ALIGNMENT REPORT

Driving a misaligned vehicle is no picnic. A wheel alignment adjusts the angles of your wheels to ensure your vehicle travels straight and evenly down the road. It can mean the difference between a smooth, comfortable ride and an unpleasant one with the steering wheel vibrating in your hands or pulling to one side.

Ensuring good wheel alignment is also beneficial to the health of your tires, reduces strain on your steering and suspension components and promotes better fuel efficiency. So, it is important that you know what your alignment reports are telling you. Watch our on-demand webinar, where our experts go over sample reports and provide first-hand tips and best practices on how to read and understand a wheel alignment report.

When is a Wheel Alignment Required?

Your wheels need an alignment if you have:

- Installed a new set of tires

- Replaced any steering or suspension components

- Experienced drivability issues, like drift, pull or off-center steering

- Noticed irregular tire wear

- Had an accident or experienced a hard impact to your suspension

What to Check Before an Alignment

Before performing an alignment, it is important to do a pre-check. Examine all tires for damage, or irregular or excessive wear, and verify that correct sizes and pressures are being used. Additionally, examine steering and suspension components for wear or damage, check for excessive weight in passenger and cargo areas and follow the proper procedures to verify curb height is correct.

Understanding Alignment Specifications

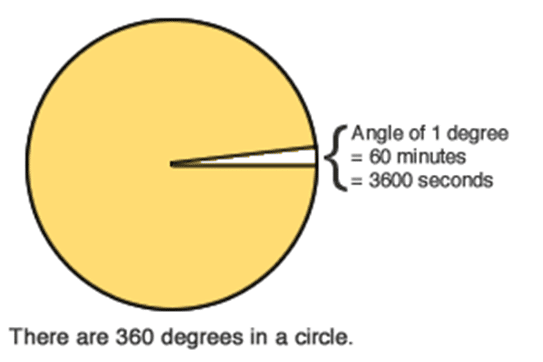

Alignment specs are usually provided in angular measurements of Degrees ( ° ) and Minutes ( ‘ ).

- A full circle is made up of 360 segments called Degrees ( ° ).

- Each Degree is broken into 60 segments called Minutes ( ’ ).

- So, 1°35’ = 1 Degree and 35 Minutes

Wheel Alignment Angles

The primary angles are toe, camber and caster, plus the thrust or tracking angle.

TOE

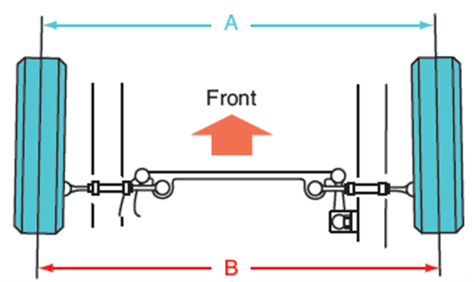

Toe compares the distances between the front and rear on a pair of tires, measured in ± degrees. Toe is also sometimes defined in linear mm or inches. The further away from center, the larger the mm or inch value. With linear toe measurements it is important to know the wheel (rim) size to calculate the angle. Luckily, there are charts or angle calculators that can help.

Excessive toe-in accelerates wear on the outer tire edges, while excessive toe-out accelerates wear on the inner tire edges. Setting toe is done by altering the length of the tie rod assembly. When the assembly is behind the pivot point, shorten it to toe-out and lengthen it to toe-in.

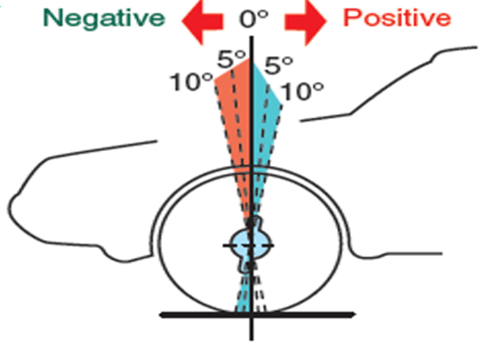

CAMBER

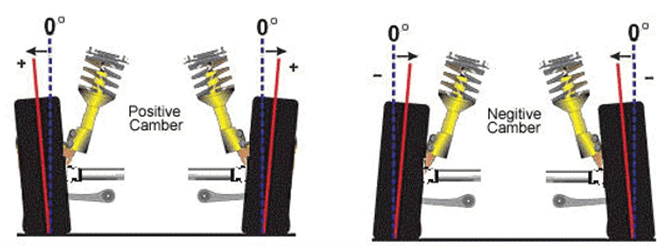

Camber is the inward or outward tilt of a tire at the top, measured in ± degrees, and it is not adjustable on all vehicles. Positive camber is when the top of the tire tilts outward, causing pull to the right and tire wear on the outer edges. Negative camber is when the top of the tire tilts inward, causing pull to the left and tire wear on the inner edges.

On MacPherson strut systems, camber may be adjusted by using an eccentric bolt on the upper strut bolt location, causing the steering knuckle to pivot on the lower strut bolt. On SLA or double- wishbone suspensions, camber may be adjusted using eccentric cams on the control arm bushings or using shims.

CASTER

Caster is the forward or rearward tilt of the spindle support arm. Measured in ± degrees, the caster on most vehicles is positive and set to 3-5 degrees. Positive caster is when the top of the spindle is tilted to the rear. This helps wheels return to center when driving and improves straight line stability at high speeds. Negative caster is when the top of the spindle is tilted to the front. This is good for immediate turning, but is unstable at high speeds, and may cause shimmy, wander or pulling to the side.

Caster may not be adjustable on all vehicles or may require the movement of the subframe to correct it. On a McPherson strut system, caster may be adjusted using special adapters and moving the upper portion of the strut in its mounting position on the chassis. Some vehicles may use a radius or strut rod to adjust caster.

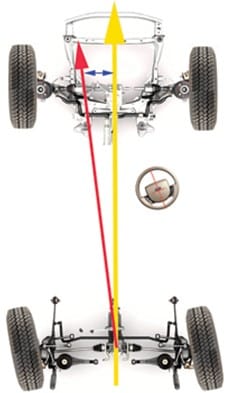

THRUST ANGLE (TRACKING)

The thrust angle is the direction of thrust set by the rear wheels, compared to the center line of the vehicle. It is set by the angle of the rear axle or the toe of the rear wheels. A thrust line to the right of the centerline is positive and to the left of the centerline is negative. An incorrect thrust angle will cause poor alignment and “dog-tracking” or “crab-walking.”

Alignment Procedures

First check the vehicle’s service manual for angle specifications and the correct adjustment points, then follow the proper procedures for 2- or 4-wheel alignment.

- 2-Wheel or Front-End Alignment: Is usually done on vehicles with a solid or mono beam rear axle. Only the front wheels will be adjusted. The thrust line should be checked, then the caster set, followed by camber and toe.

- 4-Wheel Alignment: Is usually done on vehicles with front and rear independent suspension systems. The thrust line should be checked, then adjustments should be made to rear camber then toe. Next, the front wheels should be adjusted, by first setting caster, followed by camber and toe.

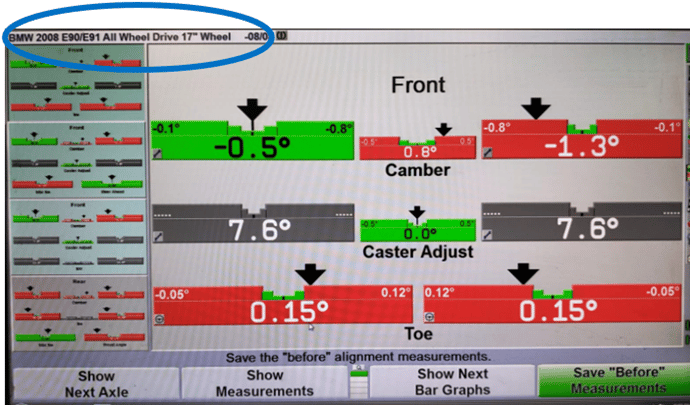

Reading an Alignment Screen

Generally, the screen can be split to focus on either front or rear wheels, with the information divided between the left and right wheels, showing the angles. Alignment specifications will be dictated by the vehicle year, make, model and other trim options, and min/max values and preferred settings will be shown.

Reading an Alignment Report

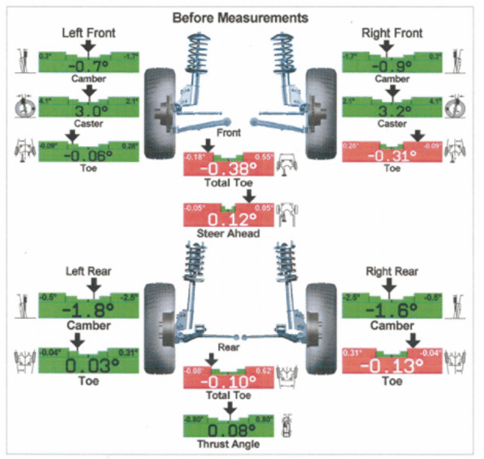

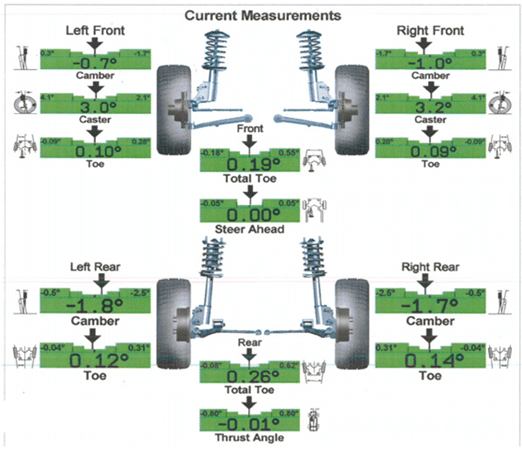

An alignment report will provide a pre-adjustment reading, or “Before Measurements,” to show the vehicle’s wheel alignment before any corrections have been made. In the example above, the vehicle has a toe-out condition on both the front and rear right wheels.

The post-adjustment reading, or “Current Measurements,” will show the vehicle’s wheel alignment after any corrections have been made. In the example above, the vehicle’s toe-out condition has been corrected and all values are in the preferred (green) range of acceptable minimums and maximums. Also, by fixing the toe angles, the total toe and steer ahead angles have been corrected.

Overall, alignment reports come in many different styles, but all should provide “pre-” and “post-” alignment values so you can be assured the job is done properly.

Top Takeaways to Note

- Pre-alignment checks are critical to make sure the car is ready to hold the alignment

- 4-Wheel alignments are not always necessary but it is always important to validate rear wheel alignment and thrust line

- Wheel alignment specifications are defined by the vehicle make, model, trim package and tire size

- Adjustments should split the difference between the Min and Max specifications

- While not all alignment angles are adjustable on all vehicles, there may be aftermarket solutions available

To take a deeper dive into reading and understanding wheel alignment reports, with many helpful examples, watch the webinar, How to Read and Understand a Wheel Alignment Report.