THE IMPACTS OF AGED, OVERLOADED AND MODIFIED SUSPENSIONS – WHAT YOU NEED TO KNOW FOR A SUCCESSFUL INSPECTION AND REPAIR

Your customer’s vehicle might not be in the same shape as when it first hit the road. Whether you’re dealing with an older vehicle, one carrying hefty loads, or a ride that’s been modified for performance or appearance, read on to learn what you need to know for a successful inspection and repair.

Suspension Geometry

Suspension geometry plays a crucial role in a vehicle’s performance. It refers to the arrangement of suspension system parts and the values of lengths and angles within it. Correct geometry ensures that components like ball joints and bushings are positioned as intended. Any changes to these pivot points can not only affect road performance but also subject components to unwanted loading forces, leading to reduced service life.

The Importance of Ride Height

Ride or curb height is a key indicators of correct suspension geometry, often overlooked during inspections and repairs. Components must be replaced at the vehicle’s correct preloaded ride height to prevent premature failure. Alignments should be done only when the vehicle is at the correct ride height, ensuring accurate camber and toe values. Always consult the factory service manual for the proper method of measuring ride height.

Aged Vehicles: Beyond Years and Mileage

Aging isn’t just about years and mileage. Even low-mileage vehicles aged 7 years or more can show signs of wear. Seasonal temperature changes, road debris, and material degradation impact suspension components.

What to look for:

- Sagging or broken springs

- Worn, seized, leaking shock absorbers/ struts/strut mounts

- Degraded, torn, leaking bushings

- Degraded, torn, leaking boots (ball joint, CV) Uneven tire wear and/or improperly (under/over) inflated tires

- Warped, damaged, out of spec components (subframe, control arms, knuckles, wheel rims)

Overloaded Vehicles: The Heavy Burden

Consistently carrying loads at or above a vehicle’s GVWR defines an overloaded vehicle. This is common in working vehicles like tow trucks or delivery vans. Diagnosing issues may be challenging when the vehicle is unloaded in the shop as issues are not readily apparent.

What to look for:

- A warped frame or chassis due to excessive overloading

- Sagging and or broken springs/shackles

- Worn, seized, leaking shock absorbers/struts/ strut mounts

- Degraded, torn, leaking bushings

- Uneven tire wear

- Excessive rear loads can alter caster, camber and toe (squat)

- Early and/or premature failure of brake, drivetrain, powertrain and suspension components due to operating above design spec and under constant additional stress forces

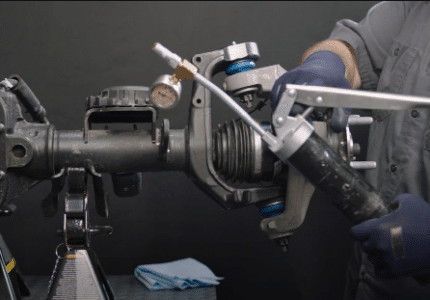

Modified Suspensions: Altered Dynamics

Vehicles with modified suspensions, whether lowered or raised for performance or appearance, present a unique set of challenges.

What to look for:

- Damage to components with low ground clearance (control arms, exhaust, oil pan)

- Worn, broken springs

- Worn, seized, leaking shock absorbers/ struts/strut mounts

- Degraded, torn, leaking bushings Degraded, torn, leaking boots (ball joint, CV)

- Uneven tire wear

- Difficult to hold alignment

- Rapid wear of wheel bearings and steering components

Summary

Understanding these conditions is crucial, as alterations to suspension geometry and ride height introduce additional stress and loading forces on components. Premature part failure and alignment difficulties can follow. So, the next time a vehicle rolls into your shop, remember to thoroughly assess for these conditions to ensure a smooth ride for your customer. For more information from the pros who know, watch the webinar, Common Issues with Modified Suspensions.