ALL YOU NEED TO KNOW ABOUT KNUCKLES: Inspecting, Cleaning and When to Replace

If your vehicle’s handling feels off, a damaged knuckle could be to blame. A key part of the suspension, the knuckle contains the wheel hub or spindle. It also serves as an attachment point for the vehicle’s steering and suspension components.

About knuckles

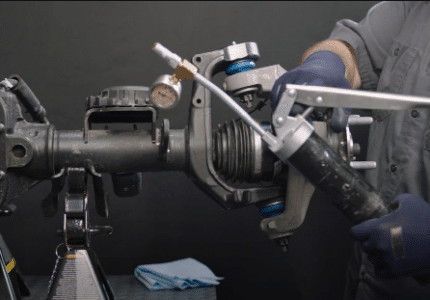

Knuckles can be referred to as steering knuckles, spindles, uprights, outer “Cs” or hubs. They are made of durable steel for heavy-duty applications or aluminum for weight and cost control on lighter-duty applications. Knuckles can serve as the mounting component for items like brake calipers, ABS sensors and wheel bearings, and they also include the connections for the tie rod end and upper and lower pivot points. When it comes to working with knuckles the best advice is clean, clean, clean.

Areas to clean

The press-in surfaces.

The ball joint needs to press all the way in – it can’t be sitting on 2 to 3 millimetres of rust or grime. The cavity must be as clean as possible to ensure the ball joint is properly seated.

The boot and fastener mating surfaces.

Clean the mating surfaces well, and even add a bit of grease to help the seating of the dust boot. Ensuring clean surfaces really goes a long way in keeping out debris and helping ball joints last longer.

Inside the stud holes and pinch bolt hole.

When working with pinch bolts, everything should slide together easily. If you think you might need a hammer, stop and re-evaluate the situation. Never hammer a pinch bolt or a ball joint stud into place. This can damage the ball joint. If it doesn’t go in easily, it’s not clean or lined up properly.

The hub mounting surfaces and inner carrier.

To make sure all components are going to come together smoothly, you need to start with clean surfaces. It is also important to ensure that the components are straight. For example, if the hub goes on and it is tilting forward because you missed some rust, you will have a camber issue. At the pivot point of the wheel, even just a millimetre of rust can mean your camber is 3 to 5 millimetres out at the tire tread out.

In addition to cleaning, it is important to inspect all attachment points for deformation, cracks and breaks. Failure to replace a worn knuckle could compromise the performance of the ball joint and potentially become a major chassis failure issue.

Take a few minutes to watch the on-demand webinar, where our experts cover all attachment points on the different types of knuckles, what to look for in your inspections, and when to replace the knuckles completely.