What Do You Need to Work on Electric Vehicles?

If an EV rolled into your shop’s parking lot, would you turn it away? If you said yes, you are not alone. According to a recent survey of shop owners, only 30 percent of shops work on EVs. Yet, service is not just about battery packs and inverters. It is also about brake and chassis work.

Just like an internal combustion engine car (ICE) or truck, EVs travel on the same roads and are subject to the same potholes, curbs and corrosive environment that can damage the suspension. However, there are several factors with EVs that can make life harder for the suspension and brakes.

Just like an internal combustion engine car (ICE) or truck, EVs travel on the same roads and are subject to the same potholes, curbs and corrosive environment that can damage the suspension. However, there are several factors with EVs that can make life harder for the suspension and brakes.

What do you need to work on EVs? The answer is not much. Like all ICE vehicles, you need the correct tools, parts and to follow the proper service procedures, for example when lifting the vehicle or replacing components.

Parts

EV parts are available from many replacement parts manufacturers. Parts like brake pads, wheel bearings and suspension components have been available from the aftermarket for some time now.

It is critical to use high-quality parts for electric vehicles for three reasons. First, there is not an internal combustion engine to mask noise coming from the suspension and brakes. Second, an EV may weigh more than the internal combustion equivalent. Last, the electric motor can generate more torque instantly than a conventional gasoline or diesel engine.

It is critical to use high-quality parts for electric vehicles for three reasons. First, there is not an internal combustion engine to mask noise coming from the suspension and brakes. Second, an EV may weigh more than the internal combustion equivalent. Last, the electric motor can generate more torque instantly than a conventional gasoline or diesel engine.

Noise is probably one of the top reasons people bring their vehicles into your shop. Internal combustion engines can help to mask noise from the suspension, driveline and brakes. With an EV, noise like squealing brakes and suspension clunks don’t compete with the engine and are immediately noticeable.

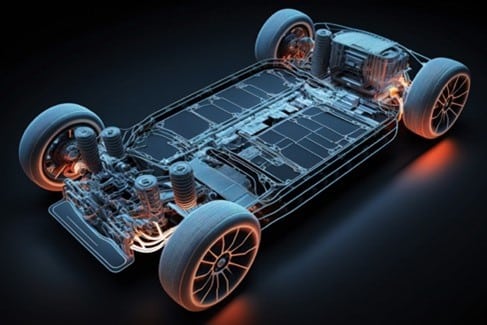

Weight is also a big issue with EVs. A Tesla Model X has a curb weight of more than 5,000 lbs. The weight can increase if the owner selects the extended-range battery and dual motor options. These options can make the Model X weigh more than a Ford F-250. As another example, the new Hummer EV weighs in at more than 9,000 lbs. This weight, combined with increased loading forces, can cause accelerated failure of some EV parts if not engineered to take real world conditions into account.

Weight is also a big issue with EVs. A Tesla Model X has a curb weight of more than 5,000 lbs. The weight can increase if the owner selects the extended-range battery and dual motor options. These options can make the Model X weigh more than a Ford F-250. As another example, the new Hummer EV weighs in at more than 9,000 lbs. This weight, combined with increased loading forces, can cause accelerated failure of some EV parts if not engineered to take real world conditions into account.

An electric motor can have more power than a gasoline engine. The torque from a 2023 Audi Q4 EV is almost equal to a Ford Mustang with the 5.0L V8. If that is not impressive, the Q4 doesn’t have to reach 3,000 rpm for peak torque. The torque delivery from the electric motor is almost instant.

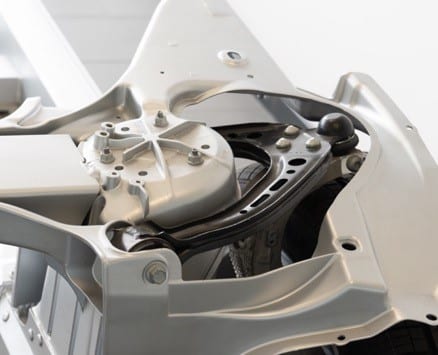

Noise, weight and power can directly impact the longevity and performance of a suspension component. Some aftermarket manufacturers have considered these factors and released parts surpassing the original factory parts.

Taking a chance on an economy part or the original part from the dealer can often result in similar failure mode. Better options are available from the aftermarket.

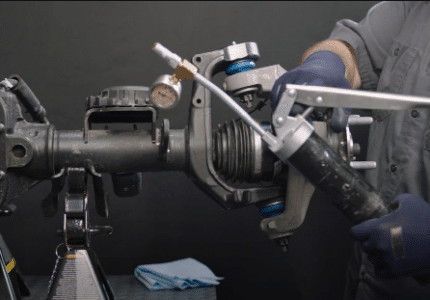

One example of these improvements can be seen in the control arms and links for the front suspension on the Tesla Model S.

You have probably seen similar front suspension designs used on Ford, Audi and Honda vehicles. It is the typical tall-knuckle design with an upper control arm and two links for the lower control arm; often referred to as a multi-link suspension.

Tesla has issued several technical service bulletins (TSB) for the front suspension of the Model S. Most TSBs focus on customer complaints about noise. In the case of the upper control arm, customers hear a squeak from the front suspension at low speeds and a vibration at higher speeds. For the lower links, wear to the ball joint can cause a clunk when braking or going over a bump.

Tesla has issued several technical service bulletins (TSB) for the front suspension of the Model S. Most TSBs focus on customer complaints about noise. In the case of the upper control arm, customers hear a squeak from the front suspension at low speeds and a vibration at higher speeds. For the lower links, wear to the ball joint can cause a clunk when braking or going over a bump.

Tesla has offered many solutions, including a special wedge washer and even replacement of the fore control links. For the upper control arm, Tesla’s answer was to seal the ball joint using a caulking gun filled with urethane. These TSBs are service advisories and campaigns. The remedies offered in the repair procedures are not typically covered if the warranty has expired.

What is the solution? Instead of using the press-fit ball joints, some chassis parts companies utilized a unitized ball joint design that encapsulates the stud and bearing. Next, some chassis parts manufacturers have improved the forging of the aft link to eliminate voids in the casting that can cause weakness and failure. Some have even improved the materials of the upper control arm to resist corrosion and the annoying squeak at low speeds.

Although some may consider Tesla as the premier EV, it’s important to point out that other manufacturers are also producing electric and hybrid electric models (HEVs). There are other types of engineered steering and suspension part improvements for these vehicles made by the aftermarket. This can include utilizing sintered metal bearings which hold up better under high heat and high loads, filling-in rubber bushing voids to better resist tearing and enhanced forging profiles which help improve assembly strength.

Other examples include corrosion-resistant galvanized brake pads and replacement tires engineered to be quiet while having a load rating able to withstand the weight of an EV. You just have to look for them.

Tools

What tools do you need to work on EVs? If you plan to work on high-voltage systems, you will need protective gloves, specialized fire extinguishers and insulated tools. If you are working on the suspension and brakes, you already own most of the tools necessary to work on an EV.

Most EV suspension designs are borrowed from an existing platform or use similar components. For example, the Ford Mach E Mustang shares the same platform as the Bronco Sport. This cross-platforming takes the surprise out of EV suspension work for the well-equipped service facility.

The one tool you will need is service information. Many information suppliers like Alldata and Mitchell are including EVs in their databases. In the menus, you may start noticing makes like Rivian and Tesla. You might also see models like the Audi e-Tron and Hyundai Ioniq.

Lifting an EV

The most significant barrier for some shops is knowing how to lift an EV. If you can’t lift an EV without damaging the underside of these vehicles, you cannot unlock the service opportunities.

The most significant barrier for some shops is knowing how to lift an EV. If you can’t lift an EV without damaging the underside of these vehicles, you cannot unlock the service opportunities.

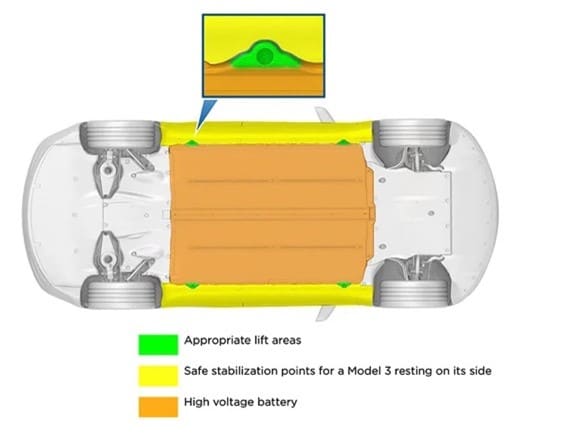

The stakes are higher for EVs because if a lift arm or jack is not correctly placed, it could damage an expensive battery pack. Some of these battery packs can cost more than $20,000 to replace. Also, there is a fire hazard if a battery pack is punctured.

Most EVs and HEVs have specific lift points stamped into the unibody. Some EVs might require special blocks inserted into holes for the lift points. Some manufacturers recommend blocks or pucks that slide over the pinch welds on the rockers.

Finding the information about the lift points can vary depending on the manufacturer. You can find the lift points in the service information. The Automotive Lift Institute’s (ALI) Lifting Points Guide includes many popular EV and HEV vehicle lift points.

When you first pull the car into the bay, the basic rules of spotting the vehicle remain the same. Always make sure the vehicle is straight and positioned in the centerline of the lift. Leave the vehicle in neutral so it can be rolled to help position the lift pads.

Most EVs have neutral on the shifter, but it is not the same neutral as an ICE vehicle. Since most EVs do not have a transmission with a parking pawl, the electric parking brake is applied even in neutral. You might have to engage a service or tow mode to roll the vehicle for lift spotting or rolling compensation during alignments. On some EVs equipped with air suspensions, the service mode will also prevent damage to the air suspension components when lifted.

If you use any type of two-post lift, you must be aware of the center of gravity. EVs and HEVs can have a different center of gravity compared to a vehicle with an internal combustion engine. Battery packs, inverters and motors can move the center of gravity to the rear or front. Again, look at the service information for advice on the center of gravity and lifting the EV.

If you ask any technician or shop owner what is “gravy” work, most will say it is brake and suspension work. These areas of service are the bread and butter for most shops. With EVs, nothing has changed.